Electron Beam

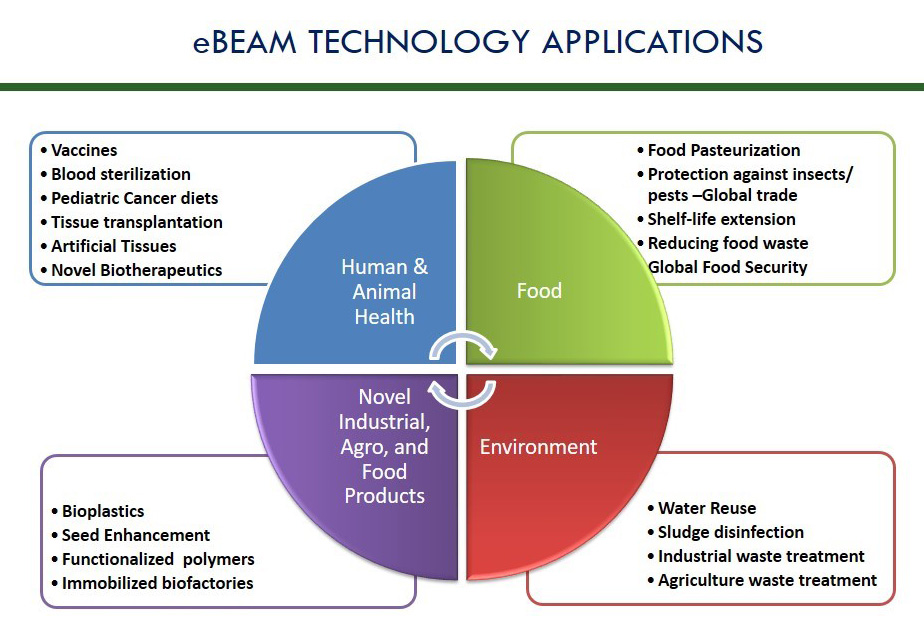

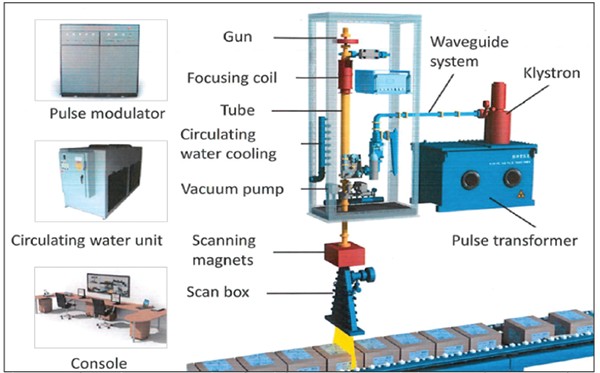

ATCOP has installed first 10 MeV 20 kW Electron Beam plant at PARAS Lahore. The electron beam (E-Beam) irradiation process uses high-energy electrons for a variety of applications. E-Beam irradiation processing is commonly used in the sterilization of medical devices, contamination control, as well as the modification of materials.

The process utilizes high energy electrons as its radiation source. The electrons, which are produced by normal electrical current, are accelerated to near the speed of light by means of a linear accelerator. The resulting energy of 10 million electron volts (MeV) and coupled with 20 kW of power, have sufficient energy to penetrate a range of materials. As a result of increased energy available from new generation equipment, this technology has established itself as a flexible and high speed process for sterilizing medical devices and pharmaceuticals. The E-beam process is also used as a method of controlling contamination in packaging, cosmetics and toiletries.

Benefits of Electron Beam

E-beam irradiation can deliver the irradiating dose in just a few seconds, meaning that the entire process can take place in minutes. As a result of this short exposure period the following benefits have been found:

- Shorter processing times

- Improved supply chain efficiencies

- Considerably less oxidative damage to the product

- Reduced color change

- No chemical residuals remain on processed products

- Clean, safe and environmentally friendly